|

HANGZHOU CANDID IMPORT & EXPORT Co.,Ltd.

|

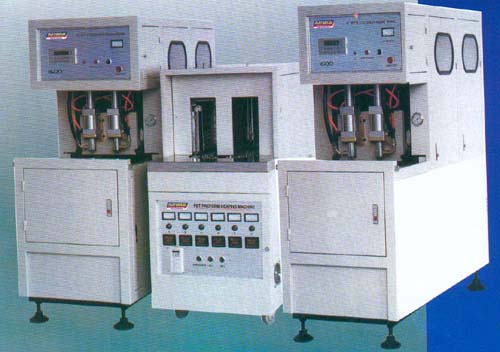

molding machine

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

This machine can produce 50ml to 2l PET bottles from 2sets of twin-cavity blow molds.Uses infrared heating system with 18units of 600watts/infrared ra

This machine can produce 50ml to 2l PET bottles from 2sets of twin-cavity blow molds.Uses infrared heating system with 18units of 600watts/infrared ray lamp to achieve uniform heating effect throughout the PET preform walls.Adjustable heating temperature according to size and characteristics of the preforms.Heating unit has a maximum loading capacity of up to 58 preforms.Heating zones temperature can be controlled as required.Heating lamps can be adjusted in upward/dowmward and forward/backward directions to maximize efficiency and to suit various preform sizes and requirements.Combined production rate of up to 1600 bottles/hour using 2sets of twin-cavity molds.PLC(Programmable Logic Control)system with a"user- friendly"(soft touch)pad.Built-in PLC can memorize and store up to 12sets of bottle blowing data.Precision time-control system to 0.01 of a second.High-quality(Festo&Burket)brands of pneumatic elements are used to ensure efficient and reliable equipment performance.Easy to operate and does not require specialized and highly-complicated training for the operation and maintenance of the machine.Ideal for beverage bottling plants and similar industrial applications.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Injection Molding Machine

Blow Molding Machine

Plastic Injection Molding Machine

Injection Blow Molding Machine

Plastic Blow Molding Machine

Pet Injection Molding Machine

More>>